Industry background informationOn May 1, the first day of the "May 1st" holiday in 2021, which is the first day of normal travel since the epidemic in 2020, many people "collapsed": they were blocked at Beijing West Railway Station. One" holiday was forced to end. Because Beijing West Railway Station, an important hub for Beijing's railway transportation, was paralyzed until late at night, tens of thousands of passengers were forced to stay in the two squares of the station for more than 10 hours. According to official reports, on May 1st, due to windy weather in Dingzhou City, the Beijing-Guangzhou High-speed Railway caused a failure of the contact network (the transmission line that supplies power to the high-speed train) due to windy weather. The Guangzhou-Guangzhou high-speed train arrived at Beijing West Railway Station late. It is not uncommon for the high-speed rail catenary to fail and power outages due to weather or foreign objects in recent years. Today, during the Qingming holiday in April this year, the Shanghai-Nanjing high-speed rail catenary was delayed due to a kite hung.

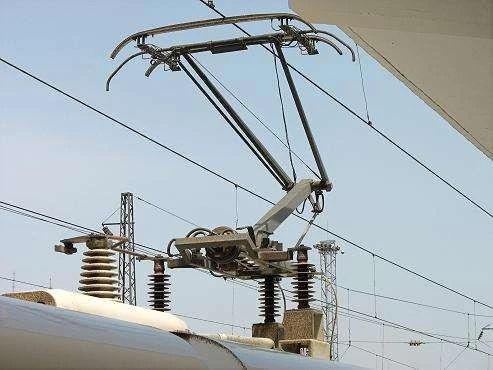

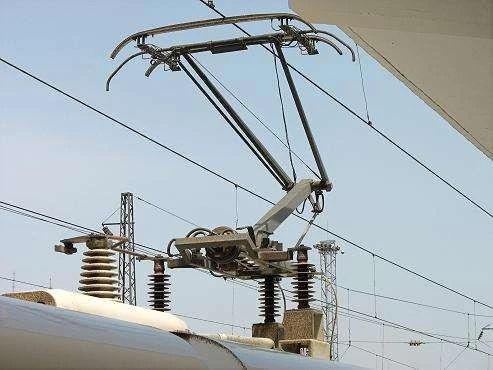

The pantograph/catenary relationship is one of the three core relationships for the safe operation of high-speed electrified railways. The good service performance of the pantograph system is the basic condition to ensure the reliable and safe operation of high-speed trains.

After 2012, the Ministry of Railways has successively issued a number of specifications such as the unified technical specifications for the 6C system, requiring the comprehensive improvement of the detection and monitoring methods and technical level of the catenary and pantograph, and the realization of full coverage inspection of the catenary and pantograph.

Solution demand analysis

In order to achieve the goal of informatization and intelligentization of railway management, we have proposed a high-speed railway pantograph intelligent detection and monitoring infrared thermal image application solution

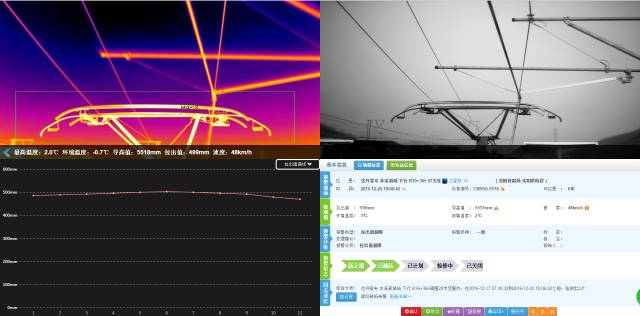

The program uses a network-type online infrared thermal imager installed on an electric locomotive to continuously monitor the temperature status of key nodes of the electrical equipment of the catenary when the electric locomotive is running, and record the monitoring data in the memory in real time. Analyze and process the real-time monitored target temperature data, generate data reports, and effectively locate the fault point of the electrical equipment of the catenary. The actual operation situation shows that the abnormal temperature information output by the system can provide a strong basis for pre-eliminating hidden troubles of catenary electrical equipment, and realize a significant improvement in the management of catenary inspection electrical equipment from maintenance operation to state operation.

Selection of product environmental adaptability requirements

The railway bow network transmits electric energy to electric locomotives, and its quality and working status directly affect the railway's transportation capacity and safety. As a catenary set in the open air, it is exposed to the outdoors all year round, and is susceptible to pollution, corrosion, friction, etc., and its quality deteriorates, which in turn affects the power transmission of locomotives and causes related safety issues. In the addition of video surveillance equipment on high-speed railways, video surveillance has extremely high requirements for the performance of front-end acquisition equipment, and due to long-term vibration, large geographic span, severe cold and heat, and limitations in size, the equipment must be earthquake-resistant and work within a wide range of temperature differences. Possess strong adaptability and 24-hour monitoring capabilities.

The system equipment is an industrial-grade product, which can meet the requirements of outdoor waterproof, moisture-proof, dust-proof and shock-proof, and can adapt to various harsh weather conditions. The outdoor equipment should have lightning protection measures.

Monitoring system functional requirements

Monitor the missing pantograph parts and abnormal pantograph network relationship. It has the functions of recording, analyzing, judging and sorting out the detected data and images, and discovering the abnormal state of the pantograph sliding plate in time to guide the maintenance of the catenary.

Program target information

Goals to be achieved by the smart monitoring program:

The current planned repair + fault repair mode is gradually changed to the state repair mode, combined with big data technology and intelligent image recognition analysis technology + thermal imaging technology

Infrared thermal imaging temperature measurement technology can observe the thermal state distribution of the pantograph surface in real time for 24 hours during the operation of the vehicle, and can collect up to one hundred infrared heat maps per second, locate and diagnose pantograph abnormalities, with non-stop operation , Non-contact, fast, intuitive features, with the back-end intelligent analysis algorithm, real-time monitoring of the current working status of the pantograph, through the thermal image analysis of the electrical equipment surface, determine and diagnose the status of the equipment and its hidden dangers and defects Early warning of potential failures and heat generation plays a key and effective role in timely detection, treatment, and avoidance of potential accidents.

Solution product selection requirements:

High detection efficiency: The online temperature measurement and detection method is adopted, and the detection efficiency is high; the selected infrared thermal imager can achieve fast, accurate temperature measurement, day and night monitoring, safe and convenient temperature measurement.

High degree of automation: the detection process and surveillance video are automatically executed;

With video acquisition, offline arc detection, high temperature abnormal point detection, real-time pantograph current acquisition, data analysis and alarm functions, alarm interface

All-weather detection: It can be detected regardless of severe weather such as rain and snow, and is not affected by climatic conditions; Advanced technology and reliability: The use of non-contact image measurement technology not only reflects advanced technology, but also greatly improves the reliability of the system. The large-screen display technology realizes the indoor visual observation of the pantograph roof conditions.

24 hours all-weather monitoring, without any light source, zero illuminance, smoke penetration, water fog monitoring; IP66 high protection level, can operate normally in bad weather. The system can work normally in harsh climatic environments, with super strong low-temperature environmental protection, as well as resistance to high temperature and high humidity. Whether it is windy or rainy, hot and humid, or low temperature and cold, it can realize continuous automatic monitoring to ensure the normal operation of key equipment monitoring in the severe cold area in the north and the high temperature and hot area in the south.

The infrared intelligent online real-time monitoring system is a real-time monitoring and monitoring system that integrates visible light, infrared thermal imaging and embedded processing technology. The system can perform automatic inspections, real-time monitoring, automatic early warning, and real-time acquisition of equipment failure status. Thermal information, combined with big data technology and intelligent image recognition and analysis technology, has the characteristics of non-stop power, long distance, safety and reliability, and high detection accuracy. It is a very effective method for online monitoring and equipment condition maintenance.

FC-R characteristic advantage analysis:

• Built-in video analyzer, capable of identifying and computing

High accuracy, fast and accurate temperature measurement, and good uniformity. In the process of scene change, the system can always get all the temperature of the observed scene in an instant, and the image uniformity is high, and it will not be caused by the change of the scene. Difference in temperature measurement

• Calibration temperature measurement function is suitable for fire detection, safety monitoring and equipment thermal temperature monitoring

• Multiple alarm notification options, including email, digital output or VMS alarm

• Very suitable for use with third-party analysis equipment, including analysis equipment provided by FLIR global partners

Has good standards, openness, integration, security, scalability and maintainability

• The thermal imager can be configured via web or mobile application

• Wide dynamic range thermal imaging, suitable for industry-leading threat detection

• Real-time online monitoring, full real-time images, no image delay

The image frame rate is 25 frames per second, fully real-time image, there will be no image pause, image lag, or jump. It avoids the difficulty of adjustment and observation caused by image lag during the process of the operator's pan-tilt rotation control and lens focal length adjustment.

Program feature application

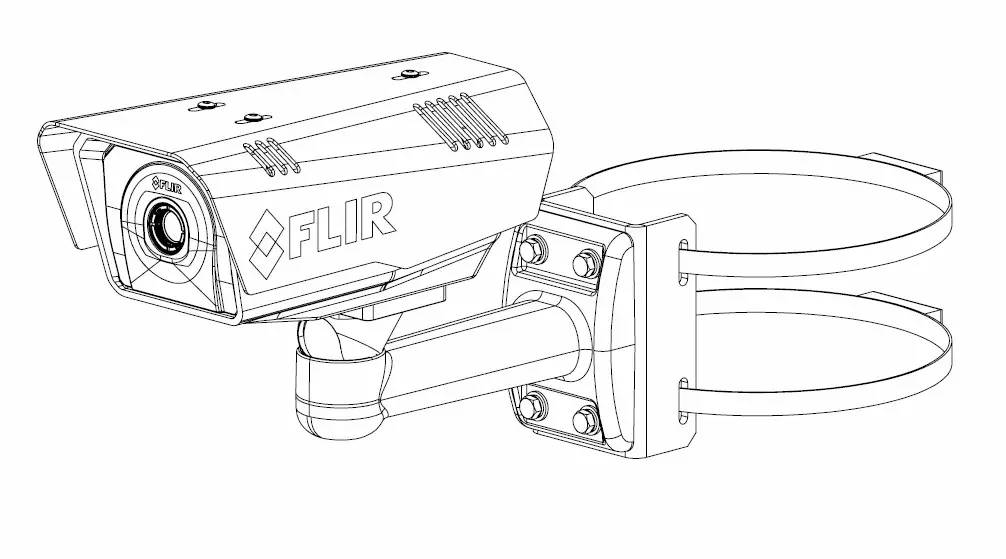

The infrared thermal imager FLIR FC-R with online temperature measurement function can realize the two functions of online monitoring + intelligent analysis.

Online Monitoring

Only when the system has not failed, it is necessary to detect the failure and take effective countermeasures. It is very important to realize the early judgment of the failure. Preventive detection has become an important means. The initial manifestation of power system failure is heat, and abnormal heat is the direct manifestation of failure. Real-time observation by high-speed infrared thermal imaging camera can collect up to 100 infrared thermal images per second. Coupled with the back-end intelligent analysis algorithm, the current working status of the pantograph can be monitored in real time, and potential faults and heating can be monitored in real time. Alarm in advance, thus effectively avoiding the occurrence of potential accidents. The infrared thermal imager is not affected by light, and it is more suitable for use in tunnels and other conditions with insufficient light. The infrared thermal imager is used to generate sparks, arcs, and contact network failures due to poor contact between the pantograph and the catenary. , Pantograph damage and faults, etc., are all well understood, so that fault points and high temperature points are truly hidden, and the safe and stable operation of the train is guaranteed.

System testing includes the following aspects

Overhead catenary catenary detection

Carbon slider wear detection

Carbon slider fracture monitoring

Detection of missing pantograph parts

Offset abnormal monitoring (bow-to-net relationship)

Inclination abnormality monitoring (bow-to-net relationship)

The system should have the function of over-limit alarm: alarm for abnormal working conditions of pantograph such as carbon sliding plate wear over-limit, carbon sliding plate fracture and defect, abnormal pantograph relationship (inclination and offset outside the normal range) and missing parts.

Overhead catenary catenary detection

The overhead catenary catenary system is suspended or above the bridge tower, and is easily affected by mechanical tension. When the traffic line is too busy, the main overhead catenary catenary is usually prone to overheating and connection failure, causing the contact line to be heated and even lose tension. Slack, the possibility of the contact wire curling around the pantograph becomes greater, and it may even cause the train to be higher than the track to block the wires. This will make the wire maintenance consume a lot of time, and there will be consequences such as safety hazards and economic losses.

The overhead catenary catenary is a suspended line system that supplies power to the locomotive or train, and conducts electricity through the pantograph. The catenary system uses at least two wires: a suspension cable or catenary, which provides support for the contact wires through height differences or connecting wires. The system is suspended above the bridge tower and is susceptible to mechanical tension. The following figure shows the junction of the two cables.

The position of the pantograph network system in the high-speed train traction power supply system

FC-R continuously collects the geographic location, measurement value or working status of each measuring point. If there is an abnormality, the system will automatically generate an alarm (sound and light alarm, SMS alarm, email alarm are optional), and notify the relevant as soon as possible Personnel, wipe out possible dangers in the bud.

Catenary detection

The main reasons for the overheating of the contact line connection are:

(1) Oxidation corrosion. Due to the external thermal defects, the conductor joints are exposed to the atmosphere for a long time, and are corroded by sunlight, rain, wind and dust condensation and chemically active gases for many years, resulting in severe rust or oxidation of the conductor contact surface of the connector, and the oxide layer will make the metal contact The resistivity of the surface increases dozens of times or even hundreds of times.

(2) The connector of the connector is loose. The conductor connection part suffers from mechanical vibration, jitter or swing under the action of wind for a long time, which makes the conductor crimping screw loose.

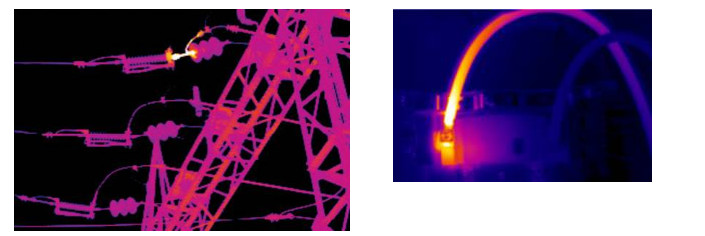

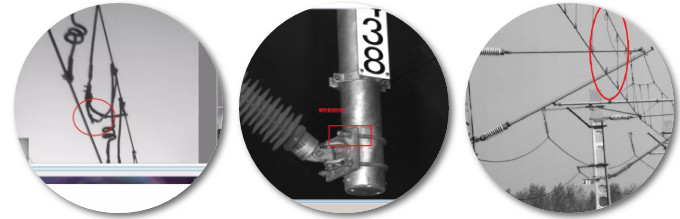

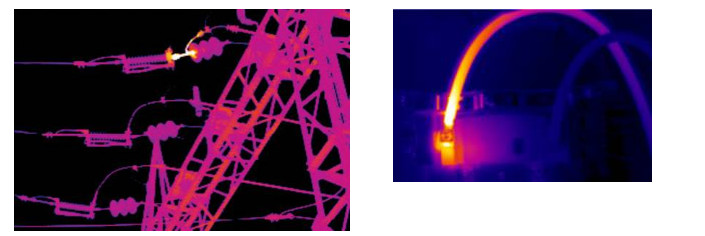

The catenary has many joints, return lines, etc., and the traction substation has transformers, fuses, circuit breakers, and all distribution lines. Using an infrared thermal imaging camera can find hidden dangers such as loose joints or poor contact (tap changer), overheating of the casing, overload, and unbalanced three-phase load (see figure). Its effects are arc, short circuit, burnout, and fire. Catenary connectors are susceptible to overheating under the influence of external factors. In severe cases, the power supply will be interrupted and the train will be out of service.

Ground monitoring requires strict control of key equipment, through infrared temperature measurement and ground fixed monitoring devices, real-time monitoring of key equipment and fault prediction. At the same time, combined with the online monitoring device for high-speed rail high-voltage cable shields, it provides guarantee for the safety of key high-speed rail equipment.

Bow net monitoring

The railway system has long used thermal imaging cameras for the safety inspection of equipment, through which it can detect thermal defects in electrical equipment and lines, which can play a very critical and effective role in the timely detection, treatment, and prevention of major accidents. effect.

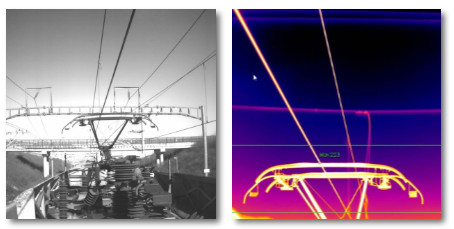

Thermal image of the top of the train's head

The infrared thermal imaging equipment can be installed on the roof of the car to detect the temperature of the connection between the pantograph and the catenary, and monitor the fault point of the catenary in real time. If the fault point is found during the train movement, it will generate an instant high temperature. The thermal imager can Record the high temperature value and the location of the fault point at this time so that the maintenance personnel can repair it in time.

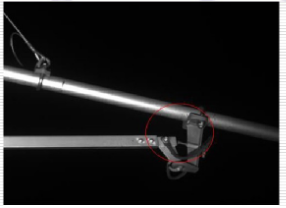

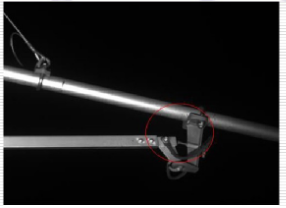

Through the size of the bolt pressure, it can be monitored in real time whether it is loose, and the safety hazard caused by the fastener falling off is avoided.

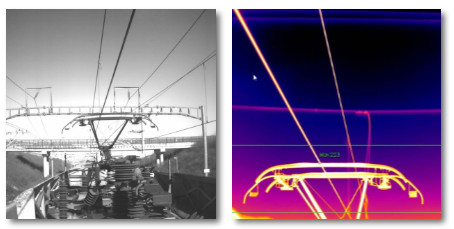

Using the "visible light" and "infrared thermal imaging" dual lenses fixed on the top of the locomotive, real-time infrared imaging and geometric parameter collection of the pantograph-net contact state of the locomotive during operation are transmitted to the terminal server through wireless communication and threshold alarms are issued.

"Visible light" and "infrared thermal imaging" dual lenses fixed on the top of the locomotive

FLIR-R series thermal imager placed in the carriage housing

The FC-R series thermal imaging camera can be used to monitor the temperature of a specific area. When the monitored temperature reaches or exceeds the preset temperature, you will receive a notification in the form of e-mail, digital output or VMS alarm.

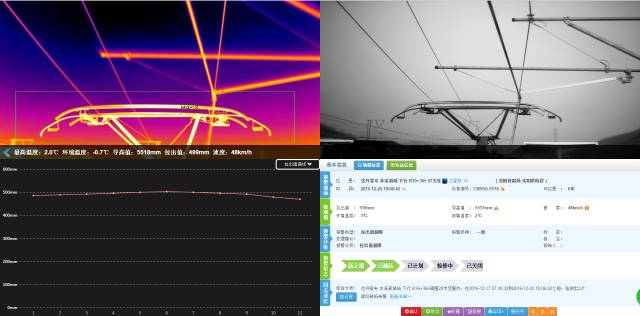

Smart monitoring application

The FLIR-R fixed infrared thermal imager with temperature measurement function can observe in real time through the infrared thermal imager for 24 hours. Up to one hundred infrared thermal images can be collected per second. Together with the back-end intelligent analysis algorithm, it can be monitored in real time. The current working state of the pantograph provides early warning of potential failures and heat, thus effectively avoiding potential accidents. The intelligent analysis system device realizes the complete collection of the image of the train roof. It can not only locate the raised pantograph image of the train through the laser precise positioning technology, but also use the image positioning method to accurately extract the high-definition image of the entire train without the raised pantograph ; Have the ability to analyze, judge, and organize the detected data.

Analysis of the advantages of intelligent monitoring solutions:

Automatic device identification management

The patented algorithm is used to automatically identify the heat map collected with the system, and the effective device target of the heat map is identified through the image registration method to ensure the effectiveness of temperature detection.

Anti-false alarm recognition system

All temperature measurements are based on effective target recognition. According to the inspection strategy, only the marked equipment can be measured. The external interference heat source is automatically eliminated, effectively preventing false alarms.

Automatic warning

If the target equipment is found to be abnormal in temperature, it will automatically alarm. The alarm information has text information and sound information, prompting the operator of the specific alarm location status information, so as to track the fault point, confirm the alarm situation and eliminate the fault.

Automatic report generation

The system software can automatically generate a single infrared image of the device contact temperature analysis report or comprehensive report, that is, the system can automatically record the temperature value of each temperature measurement, and generate a temperature report to reflect the temperature of the contact in a certain period of time Changes.

The data is comparable

The system can give the temperature change trend of all devices in the inspection strategy at the same time every day for a period of time. This temperature change trend is combined with the data of other online detection systems (such as the current change trend of the device), which can greatly facilitate the monitoring of this device. The working status of the product is accurately judged.

Automatic position calibration function.

Image recognition technology is used to automatically correct operating errors to ensure that the correct temperature state of equipment components can be collected.

Infrared thermal image intelligent monitoring program case

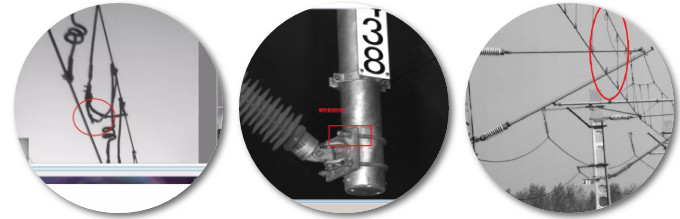

Users can view the high-definition images of the surface of the carbon skateboard and the bow groove after passing the car through the computer terminal in the monitoring room

Record the working status of the pantograph and catenary through the roof equipment, and transmit it to the individual collection devices in the electronic cabinet to generate data, and then send it to the analysis software of the computer for analysis and comparison, and check whether the collected data exceeds the standard . Intelligent recognition technology can effectively overcome the shortcomings of the system that generates a large number of pictures, manual retrieval is labor-intensive, low-efficiency, and retrieval accuracy cannot be fully guaranteed.

The device detection data is transmitted wirelessly, and the device terminal software realizes the comprehensive management of image and other data, supports partial enlargement of pictures, and image quality enhancement for users to enter and confirm defects;

Infrared thermal imaging, intelligent analysis, dynamic geometric parameters of the catenary: such as the height of the contact line, the pull-out value, the mutual position of the contact lines, etc., to measure the arcing times, arcing time and arcing rate of the pantograph.

Principle of Remote Monitoring

In the system, the infrared thermal imager collects the infrared thermal image, and the front-end thermal imager completes all the temperature measurement work, and transmits the infrared image and the original temperature measurement data to the information center or on-site workstation. There is no signal compression, no signal loss, and strong anti-interference. , To ensure the accuracy and stability of the temperature measurement data. It also measures the surface temperature of the monitoring equipment in real time, and transmits the infrared heat map and temperature data to the monitoring host through the PAL video interface and the RJ45 interface. The user can observe the operation of the field equipment in real time on the monitoring host. At the same time, the monitoring host can display the image and temperature The data is compressed and sent to the local area network through network equipment to realize real-time network monitoring.

Equipped with professional management software

By configuring the corresponding sensors and alarms, the monitoring signals are transmitted from the industrial ring network to the monitoring center, and then the data is analyzed through the supporting integrated management software. The management software continuously collects the geographic location, measurement value or working status of each measuring point. If an abnormality occurs, the system will automatically generate an alarm (sound and light alarm, SMS alarm, and email alarm are optional), and notify relevant personnel as soon as possible , To eliminate possible dangers in the bud, avoid causing large economic losses and affecting the normal operation of the railway.

Artificial intelligence analysis

In the era of big data, the integration of efficient and fast artificial intelligence solutions is the industry development trend, especially the application of infrared thermal imaging technology combined with deep learning analysis and intelligent perception monitoring.

Combination of online monitoring system and artificial intelligence analysis

At present, the analysis room has realized the full download of the high-speed rail and inter-city data every ten days when the car is added to the car, and the timely analysis of the relationship between the bow and the network provides reference data for the fine maintenance of the catenary. Analyze and identify the state of the roof and side of the vehicle through intelligent image recognition technology, and perform abnormal recognition and alarm. At the same time, it is equipped with high-speed, high-resolution image analysis and measurement technology and modern sensing technology to realize the online dynamic automatic detection of the key characteristic parameters of the pantograph and the indoor visual observation of key roof components and foreign objects on the roof, which is used for the power receiving of the EMU Bow and roof equipment inspection.

Carry out catenary high-speed video capture

High-definition image acquisition is carried out to ensure that the train forms a high-definition image without smearing when the train passes quickly, and then the image is extracted through the image intelligent recognition algorithm, so as to achieve accurate fault location. By installing a magnetic steel sensor on the trackside to accurately measure the number of axles, the bow position can be judged and the faulty bow can be accurately located.

Mass data for fine analysis

With the big data platform, it is very clear. On the platform, we can clearly view all the information of each device of each station, and each of their real-time status is displayed on the platform in time. We know that each The status and whereabouts of the equipment will also help us analyze the causes of failures and resolve each failure faster.

Real-time alarms for trains' real-time failures and abnormal conditions based on early warning conditions set based on operating experience, rapid analysis based on alarm related variables, locating the cause of the failure, and providing pre-defined failure handling guidance. At the same time, the system can combine operating conditions that are prone to failures based on operating experience. In the process of big data accumulation, it can flexibly set mode conditions and alarm content according to operating conditions to achieve flexible configuration of train warning information. When the configuration is completed , Predict the occurrence of failures in advance, and issue reminders to remind ground monitoring personnel to pay more attention to reduce train failures.

Based on in-depth mining of a large amount of historical data, the system achieves the prediction of train failures. It has accurate intelligent guidance for the handling of related failures, automatic arrangement of maintenance related work orders, materials and personnel, realizes automatic learning of unsaved failures in the expert system, and continuously automatically improves experts system. According to the system recommendations, the goal of optimizing and perfecting the entire subway network operation and maintenance management procedure strategy is achieved, and the system-level fault prediction of complex equipment is realized, that is, when the equipment may have multiple faults concurrently, the most likely faulty component is determined, and the failure time is predicted in advance. System-level failure prediction of trains and key complex equipment

Detection case analysis (the limit locator limit nail clearance parameter is unqualified)

prospect

At present, in accordance with the quarterly inspection plan announced by the Professional and Technical Section, the railway inspection department conducts quarterly inspections on the eight lines of high-speed rail, intercity and general railways in the pipeline, and conducts dense cycle online inspections on a quarterly basis, and the contact suspension of each span , Additional suspension and other equipment to conduct a comprehensive "physical examination" to achieve massive data collection and refined analysis.

Other areas of temperature measurement and early warning program

Other main application areas include: oil field-monitoring oil pipelines for oil leakage; coal piles-whether there is spontaneous combustion in high temperature, etc., power generation and distribution, substation monitoring stations, key equipment monitoring, natural gas processing, transportation and storage , Storage area fire protection, flame detection, coal storage area fire protection, timber storage area fire protection, waste storage area fire protection.